Valvula papilionis Wafer seriei YD

Descriptio:

Valvulae papilionis seriei YD "Wafer" cum flange universali norma congruit, et materia manubrii est aluminium; haec instrumentum ad fluxum in variis tubis mediis intercludendum vel regulandum adhiberi potest. Per selectionem diversorum materiarum disci et sedis obturantis, necnon per coniunctionem sine aciculo inter discum et caulem, valvula ad condiciones peiores, ut desulfurationem vacui, desalinizationem aquae marinae, adhiberi potest.

Characteristica:

1. Parva magnitudine, levi pondere, et facilis sustentatione. Ubi opus est, aptari potest.

2. Structura simplex et compacta, celeris operatio 90 graduum on-off

3. Discus bidirectionalem ferculum habet, perfectam obsignationem, sine effluxione sub pressione probata.

4. Curva fluxus ad lineam rectam vergens. Excellens regulationis efficacia.

5. Varia genera materiarum, ad diversa media applicabilia.

6. Fortis lavacro et penicillo resistentia, et aptari potest ad malas condiciones laboris.

7. Structura laminae centralis, parvus momentum aperiendi et claudendi.

8. Longa vita utilis. Probationem decem milium operationum aperiendi et claudendi sustinens.

9. Ad media abscindenda et regulanda adhiberi potest.

Applicatio typica:

1. Opera aquaria et proiectum aquarum

2. Protectio Ambitus

3. Aedificia Publica

4. Energia et Utilitates Publicae

5. Industria aedificatoria

6. Petroleum/Chemica

7. Chalybs. Metallurgia

8. Industria chartae

9. Cibus/Potus etc.

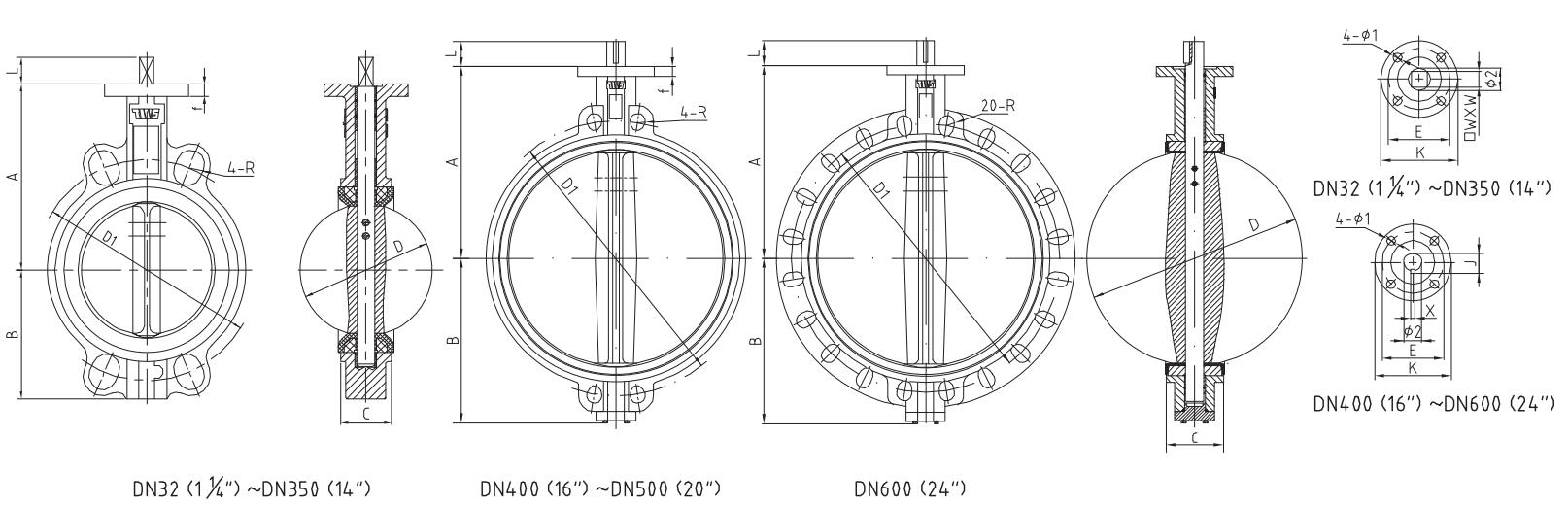

Dimensio:

| Magnitudo | A | B | C | D | L | D1 | D2 | Φ1 | ΦK | E | R1 (PN10) | R2 (PN16) | Φ2 | f | j | x | □w*w | Pondus (kg) | |

| mm | pollicem | ||||||||||||||||||

| 32 | Quarta et undecima | 125 | 73 | 33 | 36 | 28 | centum | centum | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.6 |

| 40 | 1.5 | 125 | 73 | 33 | 43 | 28 | 110 | 110 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.8 |

| 50 | 2 | 125 | 73 | 43 | 53 | 28 | 125 | 125 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 2.3 |

| 65 | 2.5 | 136 | 82 | 46 | 64 | 28 | 145 | 145 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3 |

| 80 | 3 | 142 | 91 | 46 | 79 | 28 | CLX | CLX | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3.7 |

| centum | 4 | CLXIII | 107 | 52 | 104 | 28 | CLXXX | CLXXX | 10 | 90 | 70 | R9.5 | R9.5 | 15.8 | 12 | – | – | 11*11 | 5.2 |

| 125 | 5 | CLXXVI | 127 | 56 | 123 | 28 | 210 | 210 | 10 | 90 | 70 | R9.5 | R9.5 | 18.9 | 12 | – | – | 14*14 | 6.8 |

| CL | 6 | 197 | 143 | 56 | CLV | 28 | 240 | 240 | 10 | 90 | 70 | R11.5 | R11.5 | 18.9 | 12 | – | – | 14*14 | 8.2 |

| ducenti | 8 | 230 | CLXX | 60 | 202 | 38 | 295 | 295 | 12 | 125 | 102 | R11.5 | R11.5 | 22.1 | 15 | – | – | 17*17 | 14 |

| 250 | 10 | 260 | 204 | 68 | 250 | 38 | 350 | 355 | 12 | 125 | 102 | R11.5 | R14 | 28.5 | 15 | – | – | XXII*XXII | 23 |

| trecenti | 12 | 292 | 240 | 78 | 302 | 38 | quadringenti | 410 | 12 | 125 | 102 | R11.5 | R14 | 31.6 | 20 | – | – | XXII*XXII | 32 |

| 350 | 14 | 336 | 267 | 78 | 333 | 45 | 460 | 470 | 14 | CL | 125 | R11.5 | R14 | 31.6 | 20 | 34.6 | 8 | – | 43 |

| quadringenti | 16 | 368 | 325 | 102 | 390 | 51/60 | 515 | 525 | 18 | CLXXV | 140 | R14 | R15.5 | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 | 18 | quadringenti | 356 | 114 | 441 | 51/60 | 565 | 585 | 18 | CLXXV | 140 | R14 | R14 | 38 | 22 | 41 | 10 | – | 78 |

| quingenti | 20 | 438 | 395 | 127 | 492 | 57/75 | DCXX | DCCL | 18 | CLXXV | 140 | R14 | R14 | 41.1 | 22 | 44.1 | 10 | – | 105 |

| DC | 24 | 562 | 475 | CLIV | 593 | 70/75 | DCCXXV | DCCCLXX | 22 | 210 | CLXV | R15.5 | R15.5 | 50.6 | 22 | 54.6 | 16 | – | 192 |